A nickel sheet is a thin, flat metal shape with uniform thickness. Nickel sheets are made from bullets or ingots of pure nickel. They are also made from nickel alloys. Nickel sheets are thicker than foil while thinner than nickel plates, varying between 0.006 inches and 0.250 inches. Read More…

Since 1986 Magellan has been serving the global aerospace, oil & gas, power generation, petrochemical, bio-medical, pharmaceutical and other high tech manufacturing industries. Suppliers of nickel alloys, titanium, stainless steel and duplex alloys throughout the United States and in over 45 countries.

At Metals Unlimited Aerospace, we take pride in being a trusted source for premium nickel materials that meet the exacting standards of the aerospace industry. Our expertise lies in providing high-performance nickel alloys known for their strength, corrosion resistance, and ability to withstand extreme environments.

We are Cada Stainless & Alloys, a trusted supplier of high-performance nickel materials engineered for demanding industrial environments where strength, corrosion resistance, and consistency are non-negotiable. Our operations center on sourcing and processing premium nickel and nickel-based alloys that serve critical applications across chemical processing, aerospace, power generation, marine,...

At Service Steel Aerospace, we specialize in providing premium-quality nickel products tailored to the needs of the aerospace industry. Our extensive range of nickel alloys and materials is designed to meet the rigorous demands of aerospace applications, offering superior strength, durability, and corrosion resistance.

Sierra Alloys is a manufacturing service center specializing in titanium, PH grades of stainless, VAR aircraft alloy steels and nickel based alloys. Sierra's in-house forging and hot rolling equipment serves to meet and exceed the most stringent customer requirements. We have over 30 years experience.

Need nickel, nickel alloys (200, 201, 205, 211, 233), nickel bar, sheet, strip, wire or welding wire? Call us. Our other nickel alloys include nickel-copper, nickel-chromium, copper-nickel, iron-nickel, copper nickel manganese and low OHM resistance alloys. Small or large quantities honored. Not only do we specialize in nickel and nickel based alloys we also specialize in customer satisfaction....

More Nickel Sheet Suppliers

What is a Nickel Sheet?

Nickel sheets are flat-rolled products made from pure nickel or nickel alloys, supplied in standardized dimensions to cater to a wide array of industrial applications. These metal sheets are prized for their predictable thickness, width, and length, which makes them highly desirable for efficient manufacturing, precise component fabrication, and seamless integration into complex assemblies. The uniformity and consistency in nickel sheet dimensions allow manufacturers to streamline inventory management, optimize storage and transportation, and simplify subsequent machining or forming processes.

Nickel, as a base metal, is renowned for its unique combination of properties: it is ductile, malleable, and can be rolled into extremely thin sheets without cracking or losing integrity. These characteristics make nickel sheets ideal for applications requiring both strength and formability. Other key features of nickel sheet include ferromagnetism, outstanding hardness, exceptional corrosion and oxidation resistance, as well as high electrical and thermal conductivity. When considering the purchase of nickel sheets, it is crucial to evaluate the specific nickel alloy composition—since mechanical, chemical, and processing properties can vary significantly between grades such as pure nickel (Nickel 200, Nickel 201) and specialty alloys like Inconel or Hastelloy.

Are you comparing nickel sheet suppliers or researching which type of nickel alloy sheet best fits your application? Explore our comprehensive guides and product listings to make an informed decision for your project needs.

The Process of Nickel Sheet Forming

The journey of producing high-quality nickel sheets begins with the extraction of nickel from natural ores. Nickel ore is mined using either hydrometallurgical (leaching and solvent extraction) or pyrometallurgical (smelting and refining) methods, depending on the ore type. The extracted nickel is purified through processes such as roasting, reduction, and electro-refining to achieve the desired chemical composition and purity. Commercially pure nickel sheets typically contain at least 99.6% nickel, while various nickel alloys may contain as little as 32.5% nickel, balanced with other elements to impart specialized properties for demanding environments.

Once refined, the nickel or nickel alloy is cast into billets, ingots, bars, or slabs, which serve as the starting material for sheet production. The transformation from solid metal to thin sheet involves several metallurgical processes:

- Hot Rolling: Heated billets are passed through rolling mills to reduce thickness and increase length, producing hot-rolled nickel sheets with enhanced ductility.

- Cold Rolling: After initial reduction, cold rolling is employed at room temperature to further refine the sheet, achieving exceptional surface finish, precise thickness, and improved mechanical strength.

- Annealing: Intermediate annealing steps may be used to relieve internal stresses, restore ductility, and prepare the metal for additional rolling or fabrication.

- Alternative Forming Methods: Processes such as extrusion, casting, and drawing may be used for specialized nickel sheet products or custom dimensions.

To produce nickel sheets with exacting tolerances, multiple passes through rolling mills and careful process control are necessary. Manufacturers must evaluate factors such as desired sheet thickness, gauge, length, width, and end-use requirements before determining the appropriate rolling schedule and number of passes. Secondary operations—including slitting, shearing, punching, stamping, folding, and metal spinning—can be performed to create custom nickel sheet components for specialized applications.

Curious about which nickel sheet forming process best suits your application, or how to specify the optimal gauge and alloy? Contact our technical team or review our detailed process selection guides for expert advice.

Types of Nickel Sheets

There is a wide variety of nickel sheet products available, each engineered for specific environments and performance demands. Understanding the differences between pure nickel sheets and nickel alloy sheets is critical for engineers, buyers, and OEMs looking to maximize performance and cost-effectiveness in their applications. Below are some of the most common and high-performance types of nickel sheets on the market:

Pure Nickel Sheets (Nickel 200, Nickel 201)

Pure nickel sheets—most commonly specified as Nickel 200 or Nickel 201—are composed of at least 99.6% nickel. These sheets offer excellent corrosion resistance in neutral and alkaline media, high ductility, and outstanding electrical and thermal conductivity. They are often used in chemical processing, electronics, battery manufacturing, and aerospace components requiring high purity and formability.

Nickel Alloy Sheets

Nickel alloy sheets are formulated by combining nickel with elements such as chromium, molybdenum, iron, copper, or tungsten. These alloys are engineered to enhance specific properties—such as resistance to corrosion, heat, or mechanical stress—making them suitable for demanding industries like chemical processing, oil and gas, marine, and power generation. Key nickel alloys for sheet products include:

Hastelloy C-22 Sheets

Hastelloy C-22 sheets are manufactured from a nickel-chromium-molybdenum-tungsten alloy, providing superior resistance to a broad spectrum of industrial chemicals, oxidizing agents, and reducing environments. This material is easy to weld and fabricate, making it ideal for chemical reactors, pollution control equipment, and pharmaceutical process vessels.

Hastelloy G-30 Sheets

Hastelloy G-30 sheets are high-chromium, nickel-base alloys renowned for their exceptional resistance to highly oxidizing acids (including nitric and phosphoric acids). These sheets are frequently used in fertilizer production, chemical storage tanks, and pollution control systems.

Hastelloy B-3 Sheets

Hastelloy B-3 nickel sheets are specifically engineered for resistance to non-oxidizing acids such as hydrochloric, sulfuric, and phosphoric acids. These sheets are favored in the chemical processing industry for their durability and ability to maintain integrity in harsh corrosive environments.

Hastelloy C-276 Sheets

Nickel sheets made from Hastelloy C-276 alloy are widely used for their excellent resistance to oxidizing and reducing agents, including chlorine, ferric, and cupric chlorides. Their versatility and ease of fabrication make them a staple in pollution control, pulp and paper, and chemical processing industries.

Hastelloy X Sheets

Hastelloy X nickel sheets are known for their exceptional strength and oxidation resistance at high temperatures (up to 2200°F/1204°C). They are commonly utilized in aerospace for jet engine components, afterburner sections, tailpipes, and high-temperature ducting systems.

Haynes 242 Sheets

Haynes 242 nickel alloy sheets are notable for their age-hardening response, low thermal expansion, and excellent oxidation resistance. These sheets are used extensively in gas turbine engines, chemical processing plants, and thermal processing equipment.

Other Nickel Alloys (Inconel, Monel, Alloy 400, Alloy 600, Alloy 625, Alloy 800, Alloy 825)

Sheets made from Inconel (such as Inconel 600, Inconel 625), Monel (such as Monel 400), and other high-performance alloys provide tailored solutions for applications involving extreme temperatures, aggressive chemicals, and mechanical stress. Learn more about Inconel sheet products and their unique advantages for industrial and aerospace projects.

Applications and Uses of Nickel Sheets

Nickel sheets are an essential material in a diverse range of industries due to their remarkable corrosion resistance, high strength, and workability. Wondering how nickel sheets are used in your sector? Here are some key application areas:

- Electronics and Electrical Engineering: Nickel sheets are used in electronic wiring, battery components, fuel cell plates, and electromagnetic shielding due to their electrical conductivity and magnetic properties.

- Battery Manufacturing: Nickel sheets, strips, and foils are integral in lithium-ion and nickel-cadmium battery production, providing stability, electrical connectivity, and resistance to electrolyte corrosion.

- Chemical Processing Industry: Nickel alloy sheets are fabricated into tanks, heat exchangers, reactor vessels, and piping systems that handle corrosive chemicals, acids, and alkalis.

- Oil, Gas, and Petrochemical Engineering: Nickel sheets are employed for cladding, linings, and structural components exposed to aggressive media in refineries and offshore platforms.

- Aerospace and Defense: Due to their high-temperature strength and resistance to oxidation, nickel alloy sheets are used in jet engines, rocket components, exhaust systems, and turbine blades.

- Power Generation: Components such as boiler linings, superheaters, condenser tubes, and nuclear reactor parts leverage nickel sheet’s heat resistance and longevity.

- Automotive and Transportation: Nickel sheets contribute to emissions control, catalytic converters, battery systems for electric vehicles, and specialty components exposed to harsh operating environments.

- Medical Devices and Equipment: High-purity nickel sheets are used in surgical instruments, medical implants, and diagnostic devices due to their biocompatibility and corrosion resistance.

- Marine Engineering: Resistance to seawater corrosion makes nickel alloy sheets ideal for shipbuilding, desalination plants, and offshore structures.

Benefits and Advantages of Nickel Sheets

Why choose nickel sheet for your next industrial or engineering project? Explore these key benefits that make nickel and nickel alloy sheets a top material choice:

- Exceptional Corrosion Resistance: Nickel sheets withstand attack from acids, alkalis, and saltwater, making them ideal for aggressive chemical and marine environments.

- High-Temperature Stability: Nickel alloys retain their mechanical strength and oxidation resistance at elevated temperatures, ensuring reliable performance in furnaces, turbines, and engine components.

- Superior Ductility and Formability: Nickel sheet can be readily cut, bent, stamped, welded, or formed into complex geometries without losing mechanical integrity.

- Excellent Electrical and Thermal Conductivity: Pure nickel and certain alloys offer outstanding conductivity, critical for electronics, battery, and heat exchanger applications.

- Magnetic Properties: Ferromagnetic nickel sheets are valuable for shielding and electromagnetic applications.

- Longevity and Lifecycle Cost Savings: The durability and corrosion resistance of nickel sheets translate to reduced maintenance, fewer replacements, and lower total cost of ownership.

- Versatility Across Industries: From aerospace to chemical processing, the adaptability of nickel sheet makes it a universal solution for challenging engineering problems.

How to Specify and Select Nickel Sheets

Choosing the right nickel sheet for your application involves careful consideration of several technical and commercial factors. If you're asking, "Which nickel sheet grade or thickness should I use?" or "How do I select between pure nickel and nickel alloy sheets?"—here are some important decision points:

- Alloy Composition: Select the appropriate nickel grade (e.g., Nickel 200, Inconel 625, Hastelloy C-276) based on required corrosion resistance, mechanical strength, and temperature performance.

- Sheet Thickness and Gauge: Determine the optimal thickness that balances structural requirements, weight, and formability for your specific application.

- Surface Finish and Tolerances: Consider whether you need a specific surface roughness, finish (e.g., bright annealed, matte, polished), or tight dimensional tolerances.

- Certification and Standards: Ensure compliance with relevant ASTM, ASME, or ISO standards for quality assurance and regulatory requirements.

- Fabrication Requirements: Assess whether the nickel sheet will undergo welding, forming, stamping, or other secondary processing, and choose alloys suited for those operations.

- Quantity and Lead Time: Factor in volume needs, delivery schedules, and the supplier’s production capacity to avoid delays in your manufacturing workflow.

- Cost and Budget Constraints: Compare the lifecycle cost of pure nickel sheets versus nickel alloy sheets, taking into account durability and maintenance savings over time.

Need personalized guidance? Request a quote or connect with our technical experts for tailored recommendations on nickel sheet selection for your project.

Choosing the Correct Nickel Sheet Manufacturer

To ensure you achieve the most reliable and cost-efficient outcome when purchasing nickel sheets, it is vital to evaluate and compare multiple nickel sheet manufacturers. Utilizing our extensive directory of vetted suppliers can help you identify the best partner for your needs. Each manufacturer’s profile page highlights their technical capabilities, industry certifications, inventory range, and areas of expertise, allowing you to efficiently assess their suitability for your requirements. For streamlined communication, our platform offers direct contact forms to request product details, technical documentation, or pricing quotes.

Here are some action steps to simplify your supplier search:

- Review business profiles and certifications to ensure supplier credibility and technical expertise.

- Use our patented website previewer to quickly assess each manufacturer's product offerings and focus areas.

- Submit a single RFQ (Request for Quote) form to communicate with multiple nickel sheet suppliers simultaneously—saving you time and expediting your procurement process.

- Compare responses based on lead times, pricing, minimum order quantities, and value-added services such as custom fabrication, cutting, or finishing.

Ready to connect with industry-leading nickel sheet suppliers and manufacturers? Start your supplier search now and request competitive quotes for your next project.

Frequently Asked Questions about Nickel Sheets

Looking for quick answers? Below are some common questions users ask when researching or purchasing nickel sheets:

- What is the difference between pure nickel and nickel alloy sheets?

Pure nickel sheets offer maximum corrosion resistance and electrical conductivity but may lack the mechanical strength or specialized resistance of certain alloys. Nickel alloy sheets (such as Inconel, Hastelloy, or Monel) are engineered for enhanced strength, heat resistance, or acid resistance for more demanding environments. - How do I specify the correct nickel sheet thickness?

Sheet thickness (or gauge) is selected based on application requirements, with common thicknesses ranging from ultra-thin foils (below 0.2mm) to heavy plate (>6mm). Consult technical datasheets or application engineers to determine the right gauge for your needs. - Can nickel sheets be welded or formed into complex shapes?

Yes, both pure nickel and nickel alloy sheets are highly formable and weldable. Proper selection of welding consumables and techniques is important to maintain corrosion resistance and mechanical properties. - What standards govern the production of nickel sheets?

Nickel sheets are commonly supplied to ASTM (e.g., ASTM B162, B168), ASME, or ISO specifications, ensuring consistent quality and traceability. - How are nickel sheets priced?

Pricing depends on alloy composition, sheet thickness, order volume, market nickel prices, and value-added services such as cutting, polishing, or coating. Request quotes from multiple suppliers for competitive pricing.

Explore More: Related Nickel Products and Resources

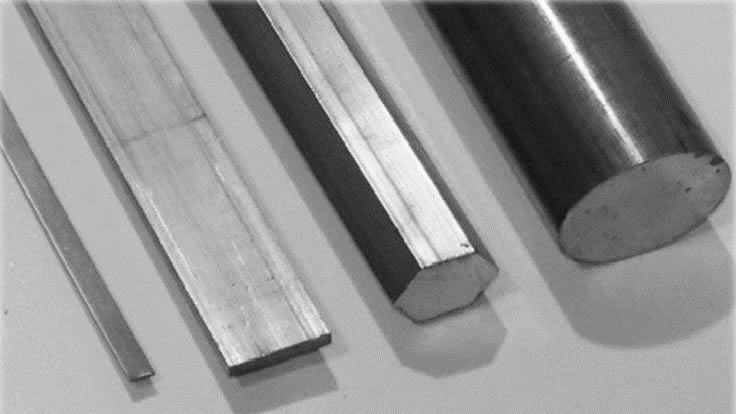

- Nickel Bar Products – Discover round, square, and hexagonal nickel bars for machining and structural applications.

- Nickel Tubes and Pipe – Learn about seamless and welded nickel alloy tubing for heat exchangers and fluid handling.

- Nickel Wire and Strip – Explore fine-gauge nickel wire for electronics, battery tabs, and specialty uses.

- Nickel Foil and Thin Sheet – Find ultra-thin nickel products for precision electronic, aerospace, and scientific applications.

- Inconel Sheet – Compare high-temperature nickel alloy sheets for aerospace and industrial use.

For further information, technical datasheets, or to discuss your nickel sheet requirements with a knowledgeable supplier, contact us today. Our team is ready to support your project from material selection through delivery and ongoing technical support. Experience the difference of working with industry-leading nickel sheet experts and maximize your project’s performance, durability, and value.

Alloy Suppliers

Alloy Suppliers Aluminum

Aluminum Aluminum Extrusions

Aluminum Extrusions Copper-Brass-Bronze

Copper-Brass-Bronze Magnets

Magnets Nickel

Nickel Stainless Steel

Stainless Steel Stainless Steel Tubing

Stainless Steel Tubing Steel Service Centers

Steel Service Centers Titanium

Titanium Tungsten

Tungsten Wire Rope

Wire Rope Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services