Inconel is a registered trademark used to describe nickel-chromium superalloys. The Inconel family is known as Chronin, Altemp, Haynes, Nickelvac, and Nicrofer because they are austenitic nickel alloys. Although the composition of Inconel alloys can vary greatly, nickel is always the element utilized in the largest amount, followed by chromium. Superalloys with a nickel-chrome base are Inconel materials. High levels of creep resistance, oxidation resistance, corrosion resistance, and strength at high temperatures characterize Inconel. Inconel can withstand extremely corrosive conditions and high temperatures. Read More…

Since 1986 Magellan has been serving the global aerospace, oil & gas, power generation, petrochemical, bio-medical, pharmaceutical and other high tech manufacturing industries. Suppliers of nickel alloys, titanium, stainless steel and duplex alloys throughout the United States and in over 45 countries.

At Metals Unlimited Aerospace, we take pride in being a trusted source for premium nickel materials that meet the exacting standards of the aerospace industry. Our expertise lies in providing high-performance nickel alloys known for their strength, corrosion resistance, and ability to withstand extreme environments.

We are Cada Stainless & Alloys, a trusted supplier of high-performance nickel materials engineered for demanding industrial environments where strength, corrosion resistance, and consistency are non-negotiable. Our operations center on sourcing and processing premium nickel and nickel-based alloys that serve critical applications across chemical processing, aerospace, power generation, marine,...

At Service Steel Aerospace, we specialize in providing premium-quality nickel products tailored to the needs of the aerospace industry. Our extensive range of nickel alloys and materials is designed to meet the rigorous demands of aerospace applications, offering superior strength, durability, and corrosion resistance.

Sierra Alloys is a manufacturing service center specializing in titanium, PH grades of stainless, VAR aircraft alloy steels and nickel based alloys. Sierra's in-house forging and hot rolling equipment serves to meet and exceed the most stringent customer requirements. We have over 30 years experience.

Need nickel, nickel alloys (200, 201, 205, 211, 233), nickel bar, sheet, strip, wire or welding wire? Call us. Our other nickel alloys include nickel-copper, nickel-chromium, copper-nickel, iron-nickel, copper nickel manganese and low OHM resistance alloys. Small or large quantities honored. Not only do we specialize in nickel and nickel based alloys we also specialize in customer satisfaction....

More Inconel Suppliers

Manufacturing Process of Inconel

Inconel alloys can be challenging to form because they rapidly harden during machining. For machining to occur, the Inconel alloy frequently needs to be in a solutionized state. But when machining Inconel, like brazing or welding stainless steel, aggressiveness and strong tools are required. The use of threaded inserts is widespread. Gas tungsten arc welding (GTAW), also known as inert tungsten gas (TIG) welding, is the most popular method utilized on Inconel alloys. However, many people have been using a recent invention, pulsed micro-laser welding, to weld Inconel alloys.

Types of Inconel

Inconel 617 is a mixture of molybdenum, nickel, cobalt, and chromium. It has enhanced strength, oxidation resistance, and metallurgical resistance. Aluminum increases Iconel 617’s ability to resist oxidation. Even when exposed to various corrosive environments, it can still resist corrosion. It is used in gas turbines, ducting, transition liners, petrochemical processing, heat-treating machinery, and nitric acid production.

Inconel 601 has nickel, iron, and chrome. It is a flexible technical material used in high-heat and corrosive environments. It is very resistant to aqueous corrosion and easy to machine and weld. It is extremely metallurgical stable and can withstand temperatures of up to 1250°F. Inconel 601 is used in manufactured combustion chambers, thermal reactors, insulting cans, and refractory cans.

Inconel 718 is a well-known nickel-chromium-cobalt alloy with excellent metallurgical stability. The Inconel 718 alloy is frequently used in ducting, gas turbines, power plants, combustion cans, and chemical processing. It is simple to fabricate, making traditional welding methods for joining it to metals simple. There are trace amounts of manganese, copper, titanium, silicone, carbon, Sulphur, phosphorus, and boron in Inconel 718.

The Characteristics of Inconel

One of Inconel's qualities is its ability to withstand extremely high temperatures. Inconel alloy maintains its strength even at very high temperatures. It has a thick, long-lasting protective oxide coating that forms when it’s heated. This coating provides outstanding corrosion resistance even at high temperatures.

Inconel succeeds in high-temperature circumstances where steel fails. The main factor causing Inconel's exceptionally high-temperature resistance is the production of the complicated intermetallic Ni3Nb in the gamma double prime phase. The intermetallic phase acts as a "glue" on the grain boundaries when heated to high temperatures, keeping the grains from expanding.

Advantages of Inconel Alloys

The compositions of different Inconel vary. Each Inconel variant has special qualities that make it useful in particular situations. For instance, Inconel 600 produces efficient components for the chemical and food processing industries due to its better resistance to oxidation and several types of corrosion. Meanwhile, Inconel 625 is a desirable option for the aerospace and marine engineering industries since it has excellent strength levels without ever undergoing heat treatment.

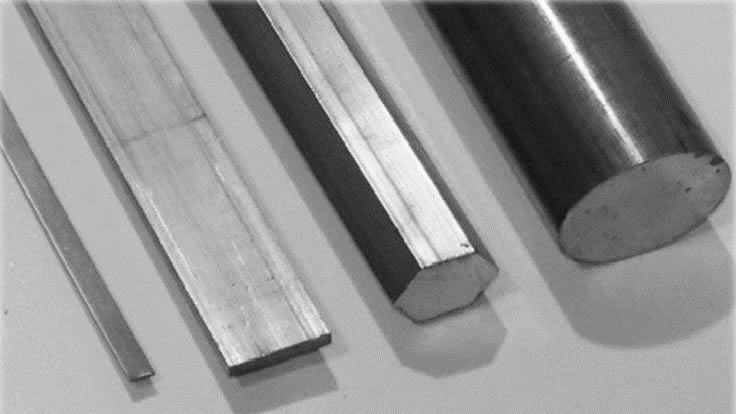

Nickel and chromium are the primary components of Inconel, so regardless of the precise alloy, Inconel is a desirable choice of material. For instance, these alloys are resistant to oxidation. Other metals like steel and aluminum typically bend when subjected to intense heat. Inconel is produced in all typical mill forms, including rod, bar, wire, wire rod, plate, sheet, pipes, tubular goods, and forging stock.

The aircraft sector is where Inconel alloys are used the most frequently. Inconel is used in space shuttles, rocket engines, 3D printing, etc. The usage of various Inconel grades is also widespread in the nuclear industry. In addition, Inconel alloys are used for:

- Jet engine

- Fuel Nozzles

- Engine Subsystems

- Afterburners

- Marine applications for saltwater

- Extraction of oil and gas

Choosing the Proper Inconel® Supplier

To ensure you have the most beneficial outcome when purchasing Inconel from an Inconel supplier, it is important to compare several companies using our directory of Inconel suppliers. Each Inconel supplier has a business profile highlighting their areas of experience, along with a contact form to directly communicate with the suppliers for more information or request a quote. Review each Inconel business website using our proprietary website previewer to quickly learn what each company specializes in. Then, use our simple RFQ form to contact multiple Inconel companies with the same form.

Alloy Suppliers

Alloy Suppliers Aluminum

Aluminum Aluminum Extrusions

Aluminum Extrusions Copper-Brass-Bronze

Copper-Brass-Bronze Magnets

Magnets Nickel

Nickel Stainless Steel

Stainless Steel Stainless Steel Tubing

Stainless Steel Tubing Steel Service Centers

Steel Service Centers Titanium

Titanium Tungsten

Tungsten Wire Rope

Wire Rope Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services