Nickel metal is a lustrous, silvery-white, gold-tinged metallic element found in nature. It is a classified as a transition metal. Nickel has five stable isotopes, an atomic weight of 58.71, an atomic number of 28, and the symbol Ni. It has a boiling point of 2730 °C, a melting point of 1455 °C, and is solid at room temperature. It is ductile, hard, ferromagnetic, and resistant to rust and corrosion. Nickel metal is mined from the earth. Read More…

Since 1986 Magellan has been serving the global aerospace, oil & gas, power generation, petrochemical, bio-medical, pharmaceutical and other high tech manufacturing industries. Suppliers of nickel alloys, titanium, stainless steel and duplex alloys throughout the United States and in over 45 countries.

At Metals Unlimited Aerospace, we take pride in being a trusted source for premium nickel materials that meet the exacting standards of the aerospace industry. Our expertise lies in providing high-performance nickel alloys known for their strength, corrosion resistance, and ability to withstand extreme environments.

We are Cada Stainless & Alloys, a trusted supplier of high-performance nickel materials engineered for demanding industrial environments where strength, corrosion resistance, and consistency are non-negotiable. Our operations center on sourcing and processing premium nickel and nickel-based alloys that serve critical applications across chemical processing, aerospace, power generation, marine,...

At Service Steel Aerospace, we specialize in providing premium-quality nickel products tailored to the needs of the aerospace industry. Our extensive range of nickel alloys and materials is designed to meet the rigorous demands of aerospace applications, offering superior strength, durability, and corrosion resistance.

Sierra Alloys is a manufacturing service center specializing in titanium, PH grades of stainless, VAR aircraft alloy steels and nickel based alloys. Sierra's in-house forging and hot rolling equipment serves to meet and exceed the most stringent customer requirements. We have over 30 years experience.

Need nickel, nickel alloys (200, 201, 205, 211, 233), nickel bar, sheet, strip, wire or welding wire? Call us. Our other nickel alloys include nickel-copper, nickel-chromium, copper-nickel, iron-nickel, copper nickel manganese and low OHM resistance alloys. Small or large quantities honored. Not only do we specialize in nickel and nickel based alloys we also specialize in customer satisfaction....

More Nickel Metal Suppliers

How Nickel Metal Is Produced

Nickel metal is a vital industrial material, valued in a wide range of sectors for its unique properties, such as corrosion resistance, high-temperature strength, and versatility as an alloying element. But how is nickel sourced and refined for commercial use? The journey of nickel begins deep within the earth's crust, embedded in naturally occurring rocks known as ores. These ores contain one or more valuable minerals that can be extracted, purified, and sold to generate revenue. Typically, metals are present in the ore. The two primary types of nickel ore are magmatic sulfide and laterites, each requiring specialized extraction and processing techniques.

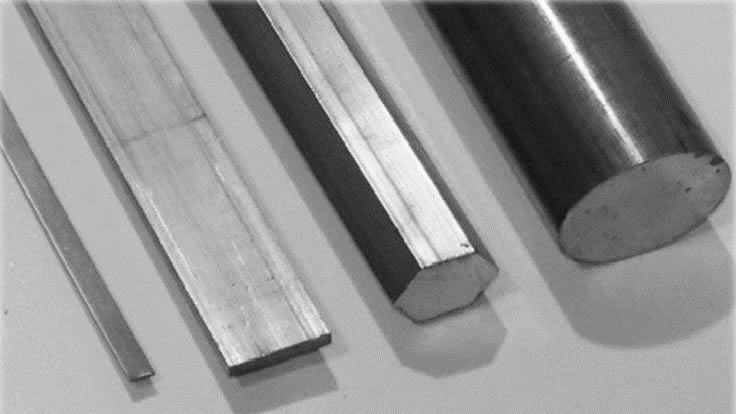

Nickel’s extraction from these ores is a multi-stage process that varies depending on the ore type. The process used to extract laterite ore is known as open-cut mining, a surface mining method that is both energy-intensive and technologically demanding. This approach is essential because laterite ores contain significant amounts of water and hydroxides, necessitating thorough drying to remove chemically bonded moisture. By contrast, sulfide ores are typically extracted through underground mining, involving a combination of casting, molding, separating, and shaping processes. Advanced techniques such as nickel extrusion, cold drawing, and electroless nickel plating are commonly used to produce a variety of nickel forms suited to industrial requirements.

Nickel Extraction and Processing

The field of extractive metallurgy plays a critical role in separating raw nickel metal from its ore. Among the most widely used methods is pyrometallurgical extraction, which involves the application of high temperatures to drive chemical reactions that separate nickel from other elements. For laterite ores, open-cut mining is often the technique of choice, utilizing heavy machinery such as front-end loaders, draglines, and large industrial shovels to remove ore from expansive open-air pits. This large-scale operation is essential for meeting the global demand for nickel in manufacturing, electronics, and other industries.

Extraction of Nickel from Sulfide Ores

Sulfide ore deposits, generally located deep underground, are accessed using sophisticated mining techniques. Once mined, the ore undergoes crushing and processing to prepare it for selective flotation, a process that efficiently separates nickel from waste material. In selective flotation, chemicals are added to create air bubbles that attract the lighter sulfide particles. As these bubbles rise, the nickel-rich sulfide particles adhere to their surfaces, allowing for easy collection. Typically, the resulting concentrate contains 6% to 12% nickel.

Magnetic separators are sometimes employed when nickel-containing sulfides exhibit magnetic properties, working in tandem with or as an alternative to flotation to boost extraction efficiency. To maximize yield and purity, waste materials are often reprocessed through additional cleaning stages. When sulfide ores contain comparable amounts of copper and nickel, a secondary flotation process is implemented to produce separate nickel and copper concentrates. This ensures optimized recovery of both valuable metals for industrial use.

What Are the Environmental Considerations in Sulfide Nickel Mining?

Environmental sustainability is increasingly becoming a top priority in nickel mining operations. Sulfide mining, while efficient, can generate tailings and waste rock that may pose risks if not properly managed. Advanced water treatment and tailings management systems help reduce environmental impact and ensure compliance with regulatory standards. If you are evaluating nickel suppliers, be sure to inquire about their environmental stewardship and sustainable mining practices.

Extraction of Nickel from Laterite Ores

Unlike sulfide ores, laterite ores are free of sulfur but contain high levels of moisture and chemically bonded hydroxides. As a result, energy-intensive drying and smelting processes are required to extract usable nickel. The drying phase, carried out in large kiln furnaces, removes moisture and leaves behind nickel oxide. Reduction processes then convert the oxide into pure nickel metal. Electric furnaces, often rated between 45 and 50 megavolt-amperes, operate at extreme temperatures ranging from 1360°C to 1610°C to achieve the necessary chemical reactions.

Modern processing facilities may employ hydrometallurgical methods such as High Pressure Acid Leach (HPAL) or Caron processes for certain laterite ore types. These techniques enable more efficient extraction of nickel and cobalt, further expanding the applications for these metals in high-performance batteries and advanced alloys.

Which Extraction Method Is Best for Your Application?

The suitability of sulfide versus laterite nickel extraction depends on factors such as ore composition, intended end-use, environmental impact, and cost efficiency. If you are comparing nickel suppliers or considering direct investment in nickel materials, understanding the source and processing method can guide your procurement decision. Jump to supplier selection tips.

Types of Nickel Metal

Nickel’s unique properties make it ideal for alloying with other metals, resulting in a broad array of nickel alloys tailored to specific industrial applications. Common alloying partners include chromium, cobalt, copper, and iron, each imparting distinct characteristics to the finished product. Here’s a closer look at the most widely used nickel metal types and their key properties.

Brushed Nickel

Brushed nickel is produced by polishing nickel with a wire brush or abrasive surface, resulting in a matte finish with fine, patterned lines. This treatment not only enhances its appearance but also improves resistance to corrosion. However, brushed nickel may develop a milky white patina over time, especially with exposure to air and moisture. This patina can be easily removed with mild cleaners or a water-and-vinegar solution. Brushed nickel is a popular choice for creating stylish, durable hardware such as doorknobs, light fixtures, and kitchen faucets, particularly in residential and commercial interior design.

Cupro Nickel

Cupro nickel is a robust alloy primarily composed of copper (60–90%) with nickel, iron, and manganese. Its silver hue, high ductility, and excellent thermal conductivity make it invaluable for harsh environments. Most notably, cupro nickel resists corrosion from seawater, making it the preferred material for marine engineering, shipbuilding, and desalination plants. Additional applications include heat exchangers, condensers, and offshore oil and gas infrastructure. If you’re seeking a material for high-salinity or corrosive environments, cupro nickel offers exceptional longevity and performance.

Nickel 200

Nickel 200 is a commercially pure wrought nickel alloy (99.6% purity) recognized for its outstanding mechanical properties, resistance to caustic alkalis, and superior thermal and electrical conductivity. With minor additions of sulfur, carbon, silicon, copper, manganese, and iron, Nickel 200 is widely used in chemical processing plants, food handling equipment, electronic components, and aerospace applications. Its ability to withstand extreme environments makes it ideal for pipelines, rocket engines, and electrical conductors. When you need a high-purity, corrosion-resistant nickel material, Nickel 200 is a top choice.

Casting Alloys

Nickel casting alloys are formulated by melting nickel with other elements and pouring the molten mixture into molds. This process enables precise fabrication of complex shapes and components, which are then solidified and finished for use in demanding industrial environments. Nickel casting alloys are celebrated for their strength, resistance to heat, corrosion, and wear, making them an essential choice for power generation turbines, automotive parts, and heavy-duty machinery. If your application requires custom-shaped, high-performance metal parts, nickel casting alloys are a versatile and reliable solution.

Nichrome Alloy

Nichrome is a nickel-chromium alloy prized for its exceptional resistance to high temperatures and electrical conductivity. Its silvery-gray appearance and robust performance make it a staple in the production of resistance wires, heating elements for household appliances (such as toasters and space heaters), and industrial furnaces. Nichrome is also used in dental restorations, flame testing, ceramics, and as bridge wire in electric ignition systems, including electric matches and model rocket igniters. For applications requiring consistent performance under intense heat, nichrome alloys are unparalleled.

Which Nickel Alloy Is Right for Your Project?

Choosing the appropriate nickel alloy is crucial to achieving optimal results in your manufacturing process or final product. Consider factors such as corrosion resistance, mechanical strength, conductivity, and application-specific requirements. Explore our supplier directory to connect with specialists in custom nickel alloys.

Applications and Uses of Nickel Metal

Nickel’s versatility ensures its widespread use across multiple sectors and industries. As an alloying metal, nickel enhances the properties of iron, copper, chromium, and other metals, enabling the creation of advanced materials for demanding environments. Here are some of the most common and impactful uses of nickel metal:

- Aerospace and Aviation: Nickel-based superalloys are integral to jet engines, turbines, and exhaust systems, where extreme temperature and corrosion resistance are paramount.

- Marine Engineering: Cupro nickel and other nickel alloys are employed in shipbuilding, offshore oil platforms, and desalination plants, thanks to their durability in seawater and harsh environments.

- Chemical Processing: Nickel’s resistance to acidic and alkaline conditions makes it ideal for chemical reactors, heat exchangers, and storage vessels.

- Energy and Power Generation: Nickel alloys are used in nuclear reactors, fossil fuel plants, and renewable energy systems for their strength and longevity.

- Electroplating: Nickel is a popular choice for decorative finishes as well as for corrosion protection in automotive, electronics, and consumer goods.

- Battery Manufacturing: Nickel is essential in rechargeable battery systems, including nickel-cadmium (NiCd), nickel-metal hydride (NiMH), and lithium-ion batteries used in electric vehicles, power tools, and backup power supplies.

- Electronics: Nickel is used in connectors, switches, and circuit boards, contributing to enhanced conductivity and reliability.

- Medical Devices: Nickel alloys are chosen for surgical instruments and implants due to their biocompatibility and resistance to sterilization processes.

- Food Processing: Nickel alloys are used in equipment and piping systems where cleanliness, corrosion resistance, and durability are essential.

How Do You Decide on the Best Nickel Material for a Specific Industry?

When selecting nickel or nickel alloys for a project, consider the environmental conditions, regulatory standards, mechanical requirements, and the cost-effectiveness of available options. Consulting with a knowledgeable supplier can help you identify the ideal grade and form factor for your needs. Review our supplier directory or contact multiple suppliers for expert advice and custom quotes.

Benefits of Nickel Metal and Nickel Alloys

What makes nickel the preferred choice for so many critical applications? Here are some of the top benefits that nickel and its alloys bring to the table:

- Corrosion Resistance: Nickel’s inherent resistance to oxidation and corrosion extends the lifespan of components in harsh chemical, marine, and industrial environments.

- High-Temperature Strength: Nickel alloys maintain structural integrity and performance even at elevated temperatures, making them essential for engines, turbines, and furnaces.

- Excellent Ductility and Toughness: Nickel’s malleability allows it to be fabricated into complex shapes and withstand mechanical stress without failure.

- Superior Conductivity: Both thermal and electrical conductivity are enhanced by nickel, supporting its use in electronics, batteries, and heat exchange systems.

- Versatility in Alloying: Nickel can be combined with a wide variety of metals, allowing for the customization of properties to suit specific engineering challenges.

- Biocompatibility: Certain nickel alloys are suitable for medical implants and surgical instruments due to their compatibility with biological tissues and resistance to sterilization.

How Does Nickel Compare to Other Industrial Metals?

Nickel stands out from metals like stainless steel, titanium, and aluminum for its unique blend of corrosion resistance, strength, and workability. If you’re weighing the pros and cons of nickel versus alternative materials, consider how each aligns with your performance requirements, budget, and industry standards. Get tailored recommendations from our supplier network.

Choosing the Correct Nickel Metal Supplier

Finding a reliable nickel metal supplier is essential for ensuring material quality, supply consistency, and technical support. When sourcing nickel products—whether pure nickel, nickel alloys, or finished components—comparing multiple suppliers is the best way to secure competitive pricing and technical expertise.

- Use our directory of nickel metal suppliers to browse companies with proven experience in nickel extraction, refining, manufacturing, and supply chain management.

- Each supplier profile features details on capabilities, certifications, industries served, and available products—helping you quickly identify those best suited to your project requirements.

- Take advantage of our proprietary website previewer to gain an in-depth understanding of each company’s specialties and customer service standards before making contact.

- Request information or a quote directly through our user-friendly contact form. Compare responses from multiple suppliers to evaluate factors such as pricing, lead times, technical support, and customization options.

What Factors Should You Consider When Selecting a Nickel Supplier?

- Product Range: Does the supplier offer the specific grade or alloy of nickel you need, in the right shapes and sizes?

- Quality Certifications: Are they ISO certified or compliant with other relevant industry standards?

- Supply Chain Reliability: Can they deliver materials on time and in the quantities you require?

- Technical Support: Do they provide engineering assistance or custom alloy development?

- Reputation and Experience: What feedback do they have from previous clients in your sector?

- Pricing and Payment Terms: Are the costs competitive and payment terms flexible for your operation?

Ready to get started? Review each nickel metal business website using our proprietary website previewer to quickly learn what each company specializes in. Then, use our simple RFQ form to contact multiple nickel metal companies with the same form. For tailored advice or to request samples, reach out now and connect with trusted nickel suppliers ready to meet your needs.

Frequently Asked Questions (FAQ) About Nickel Metal

- What is the current price of nickel metal, and what factors influence market value?

Nickel prices can fluctuate based on global supply and demand, mining output, geopolitical factors, and usage trends in industries like stainless steel, batteries, and electronics. For the latest pricing or to request a quote, contact suppliers directly. - How do I choose the right nickel alloy for a corrosive environment?

Consider alloys like cupro nickel or Nickel 200, which are engineered for maximum corrosion resistance. Consult with suppliers for recommendations based on your operational environment. - Can nickel materials be recycled?

Yes! Nickel is highly recyclable, and many suppliers offer recycled or sustainably sourced nickel products. Check supplier certifications for sustainability credentials. - What are the lead times for nickel materials?

Lead times vary by product type, quantity, and customization requirements. Request estimates from multiple suppliers to compare options. - Are there restrictions or regulations on importing nickel?

Regulations and tariffs may apply depending on your location and the origin of nickel products. Work with experienced suppliers for guidance on compliance and logistics. - What industries benefit most from nickel and nickel alloys?

Key sectors include aerospace, marine, chemical processing, energy, automotive, medical device manufacturing, electronics, and construction.

Explore More Resources and Connect with Nickel Suppliers

Nickel metal and nickel alloys are foundational to modern industry. Whether you're developing advanced batteries, designing robust marine equipment, or specifying materials for aerospace applications, finding the right nickel product and supplier is critical. Use our supplier directory to streamline your sourcing process, leverage expert advice, and ensure your project’s success. For more information, industry updates, or to request a tailored quote, contact us today and start your journey with trusted nickel metal suppliers.

Alloy Suppliers

Alloy Suppliers Aluminum

Aluminum Aluminum Extrusions

Aluminum Extrusions Copper-Brass-Bronze

Copper-Brass-Bronze Magnets

Magnets Nickel

Nickel Stainless Steel

Stainless Steel Stainless Steel Tubing

Stainless Steel Tubing Steel Service Centers

Steel Service Centers Titanium

Titanium Tungsten

Tungsten Wire Rope

Wire Rope Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services