A nickel bar is a transition metal shaped like a square, triangular or circular rod. Nickel bars have high electrical and heat conductivity. Nickel naturally occurs as a metal element with a gold-tinged, silvery-white, shiny appearance. Nickel is mined beneath the earth’s surface. Although corrosion-resistant and hard, nickel bars retain ductile and malleable properties. Nickel also has ferromagnetic properties. Read More…

Since 1986 Magellan has been serving the global aerospace, oil & gas, power generation, petrochemical, bio-medical, pharmaceutical and other high tech manufacturing industries. Suppliers of nickel alloys, titanium, stainless steel and duplex alloys throughout the United States and in over 45 countries.

At Metals Unlimited Aerospace, we take pride in being a trusted source for premium nickel materials that meet the exacting standards of the aerospace industry. Our expertise lies in providing high-performance nickel alloys known for their strength, corrosion resistance, and ability to withstand extreme environments.

We are Cada Stainless & Alloys, a trusted supplier of high-performance nickel materials engineered for demanding industrial environments where strength, corrosion resistance, and consistency are non-negotiable. Our operations center on sourcing and processing premium nickel and nickel-based alloys that serve critical applications across chemical processing, aerospace, power generation, marine,...

At Service Steel Aerospace, we specialize in providing premium-quality nickel products tailored to the needs of the aerospace industry. Our extensive range of nickel alloys and materials is designed to meet the rigorous demands of aerospace applications, offering superior strength, durability, and corrosion resistance.

Sierra Alloys is a manufacturing service center specializing in titanium, PH grades of stainless, VAR aircraft alloy steels and nickel based alloys. Sierra's in-house forging and hot rolling equipment serves to meet and exceed the most stringent customer requirements. We have over 30 years experience.

Need nickel, nickel alloys (200, 201, 205, 211, 233), nickel bar, sheet, strip, wire or welding wire? Call us. Our other nickel alloys include nickel-copper, nickel-chromium, copper-nickel, iron-nickel, copper nickel manganese and low OHM resistance alloys. Small or large quantities honored. Not only do we specialize in nickel and nickel based alloys we also specialize in customer satisfaction....

More Nickel Bar Suppliers

Production and Extraction of Nickel Bars

Nickel, a critical industrial metal, is primarily mined from the earth’s crust before being processed into nickel bars, billets, rods, and other semi-finished and finished products. The extraction process for nickel ore typically involves both hydrometallurgical and pyrometallurgical methods, each suited to the type of ore and desired purity. Hydrometallurgical extraction is often used for laterite ores and involves leaching nickel from its ore using chemical solutions, while pyrometallurgical extraction harnesses high temperatures to smelt nickel from sulfide ores.

After mining, nickel ore undergoes crushing and concentration to separate valuable nickel minerals from waste rock. The ore is then subjected to various roasting and reduction techniques, removing impurities and refining the nickel content. The resulting refined nickel is a silvery-white, lustrous metal, valued for its high corrosion resistance, ductility, and unique physical and chemical properties.

Refined nickel can be used in its pure form or alloyed with other metals to enhance specific properties, depending on the intended industrial application. For nickel bar production, the metal is heated to a molten state and shaped using processes such as extrusion—forcing the hot nickel through a series of dies to achieve precise bar shapes and sizes. This extrusion process ensures uniformity and strength in the final product.

More commonly, however, cold-drawing is employed due to nickel’s inherent malleability and heat resistance. In cold-drawing, solid nickel stock is pulled through a series of progressively smaller dies at room temperature, reducing its diameter and increasing its mechanical strength. After drawing, the nickel bars are cut to specified lengths, inspected for dimensional accuracy, and prepared for distribution.

Nickel bars are often used as starting stock for further manufacturing processes, including bending, turning, milling, drilling, grinding, forging, and reaming. Additionally, these bars serve as feedstock for melting and alloying operations—most notably for the production of stainless steel and other high-performance alloys. When sourcing nickel bar stock, manufacturers must evaluate factors such as purity, alloy composition, mechanical properties, and cost to ensure suitability for the intended application. Consulting with reputable nickel suppliers is recommended for optimal results.

Nickel resources are primarily found in two types of ore deposits: laterites and magmatic sulfide deposits. Laterite ores are generally surface-mined and processed through hydrometallurgical techniques, while magmatic sulfide ores, found deeper underground, are typically processed using pyrometallurgical methods. Understanding the differences in ore types and extraction methods is crucial for buyers seeking specific grades or forms of nickel bar.

Nickel extraction and processing: The field of extractive metallurgy governs the processes used to obtain nickel from its ores. The pyrometallurgical extraction process is particularly common, utilizing furnaces and high-temperature chemical reactions to extract and purify nickel metal. This method is especially effective for nickel sulfide ores, which can be smelted to form a high-grade matte—a mixture of nickel and iron.

Nickel extraction from sulfide ores: For sulfide ores, the ore is first crushed and ground, then subjected to froth flotation—a process that separates nickel-rich minerals from gangue. Magnetic separators may also be used to enhance separation. The resulting nickel concentrate may undergo further leaching with ammonia or sulfuric acid, and is then smelted in a rotating converter. The exothermic chemical reactions between sulfur, iron, and oxygen within the converter generate much of the heat necessary for smelting. The resultant product is refined to produce high-purity nickel suitable for bar production.

Nickel extraction from laterite ores: Laterite ores lack sulfur and are characterized by high moisture content. These ores require extensive drying and energy input to achieve the temperatures necessary for nickel extraction. Laterite-derived nickel is typically processed using hydrometallurgical methods such as high-pressure acid leaching (HPAL), which dissolves nickel and cobalt from the ore using sulfuric acid. The resulting solutions are then purified and precipitated to recover nickel in a form suitable for bar stock manufacturing.

Nickel Bars Material Properties

A nickel bar is a solid, straight rod or plank-shaped product composed primarily of high-purity nickel or nickel alloy. As a chemical element, nickel (atomic number 28) boasts a unique combination of properties that makes it valuable for a wide range of metallurgical and engineering applications. Nickel bars are known for their exceptional toughness, ferromagnetic behavior, outstanding corrosion resistance (even in harsh chemical environments), ductility, malleability, and heat resistance. These properties make nickel bars and rods indispensable in industries such as aerospace, chemical processing, power generation, and marine engineering.

Although the term "nickel bar" often refers to pure nickel, most nickel bars on the market are actually alloys in which nickel is the predominant element. The alloying process tailors the bar’s properties to suit specific requirements such as increased strength, enhanced corrosion resistance, or improved machinability.

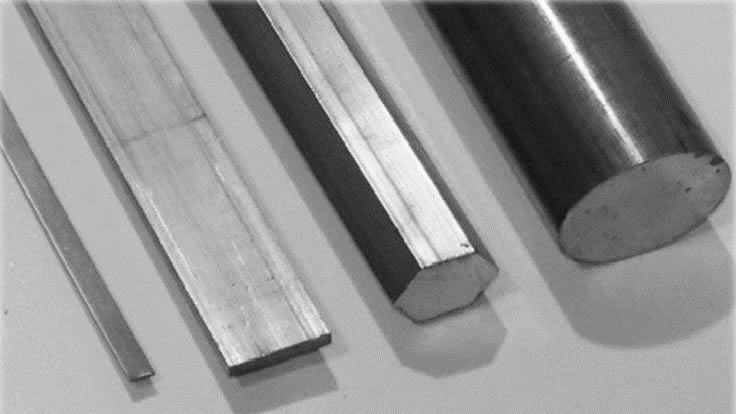

Common nickel alloys available in bar form include Hastelloy C276, Cupro Nickel (also known as Cu-Ni), Nickel 200, Nickel 500, Inconel 600, and Inconel 718. While rectangular nickel bars are the most prevalent, these bars can also be produced in round, square, hexagonal, or custom cross-sectional shapes, depending on customer specifications and end-use requirements.

Shaping of Nickel Bars

Once refined, nickel is processed into bars through a variety of shaping and forming techniques. The most common manufacturing methods for nickel bars include:

- Nickel Extrusion: Molten nickel is forced through a die to create bars of specific cross-sectional profiles. This process is ideal for producing long, continuous bars with consistent dimensions.

- Cold Drawing: Solid nickel or nickel alloy billets are pulled through a series of dies at room temperature, improving surface finish and increasing tensile strength. Cold-drawn bars are preferred for applications where dimensional accuracy and mechanical performance are critical.

- Electroless Nickel Plating: This process deposits a uniform layer of nickel onto base metal bars, enhancing surface properties such as corrosion resistance and hardness. Electroless plating is widely used for precision components and specialty applications.

- Hot Rolling and Forging: Some nickel bars are formed by rolling or forging heated nickel billets into the desired shapes and sizes, optimizing grain structure and mechanical properties.

Looking for more details about nickel bar manufacturing? What is the difference between hot-rolled and cold-drawn nickel bars? Contact our experts for in-depth technical guidance and custom bar solutions.

Types of Nickel Bars

Nickel is often alloyed with other elements to create materials with enhanced strength, corrosion resistance, and unique functional characteristics. The most common nickel-containing alloy is stainless steel, but many other specialty alloys exist. Understanding the differences among various nickel bar types can help buyers select the best material for their specific needs.

Cupro Nickel (Cu-Ni Alloy)

The cupro-nickel alloy is formed by combining copper with nickel, manganese, and iron, resulting in a lustrous silver color. This alloy exhibits excellent thermal conductivity, high tensile strength, and outstanding resistance to corrosion in marine and chemical environments. Cupro-nickel bars are highly ductile and are commonly used in seawater piping, heat exchangers, condenser tubes, and marine engineering components. Their resistance to biofouling also makes them ideal for military equipment and desalination plants.

Hastelloy Nickel Alloys

Hastelloy is a family of nickel-based superalloys renowned for their exceptional resistance to acids, particularly in oxidizing and reducing environments. Common grades such as Hastelloy C4, Hastelloy C22, and Hastelloy C2000 differ in their chromium, iron, cobalt, manganese, and molybdenum content, allowing engineers to select the optimal composition for severe service conditions. Hastelloy nickel bars are extensively used in chemical processing, pollution control, power generation, and oil & gas industries where reliability and longevity are paramount.

Inconel Alloy Bars

Inconel alloys contain a high percentage of nickel, frequently alloyed with chromium and iron. Inconel bars are engineered for applications that demand superior strength, oxidation resistance, and corrosion resistance under extreme temperatures and mechanical stress. These properties make Inconel bars an optimal choice for aerospace, turbine engines, exhaust systems, and high-pressure chemical processing. However, their robust nature can also make Inconel alloys more challenging to machine and shape compared to other materials.

Kovar Alloy Bars

Kovar is a nickel-iron-cobalt alloy characterized by its low coefficient of thermal expansion, making it ideally suited for applications that require dimensional stability across wide temperature ranges. Kovar nickel bars are used in scientific instrumentation, X-ray equipment, microwave tubes, light bulbs, vacuum tube conductors, and hermetic seals. The unique expansion properties of Kovar ensure reliable performance in high-precision electronic and scientific assemblies.

Monel Alloy Bars

Monel is an alloy composed primarily of nickel and copper, with additions of manganese, carbon, silicon, and iron. Monel bars are renowned for their excellent strength, malleability, and exceptional resistance to corrosion, particularly in acidic and alkaline environments. Applications for Monel nickel bars include boilers, kitchen sinks, marine fittings, musical instruments, gasoline tanks, and chemical processing equipment. Their workability and resilience make Monel a popular choice for demanding industrial settings.

Nickel 200 and Nickel 201

Nickel 200 is a commercially pure (99.6% minimum) wrought nickel alloy, with trace amounts of manganese, sulfur, carbon, copper, and silicon. Nickel 201 is a low-carbon variant with enhanced resistance to embrittlement at high temperatures. Both grades offer excellent mechanical properties, high electrical and thermal conductivity, and outstanding resistance to caustic alkalis and neutral/alkaline salt solutions. Nickel 200 and 201 bars are widely used in chemical processing, electronics, food handling, synthetic fiber production, and marine components.

Applications of Nickel Bars

Nickel bars are utilized in a diverse array of industries and engineering sectors due to their unique combination of strength, corrosion resistance, and thermal stability. Key applications and end-uses include:

- Piping and Tubing: Used in chemical processing plants, desalination systems, and marine environments due to their resistance to corrosion and scaling.

- Rocket Motors and Missile Components: Nickel alloys withstand extreme temperatures and stress, making them essential for aerospace and defense applications.

- Aerospace Components: Employed in jet engines, turbine blades, airframes, and fasteners where high performance and reliability are critical.

- Food Handling Equipment: Chosen for their hygienic properties and resistance to acidic and alkaline substances in food processing facilities.

- Automotive Components: Utilized in exhaust systems, fuel tanks, and structural parts requiring durability and corrosion resistance.

- Heat Exchangers: Essential in HVAC, power generation, and petrochemical plants for efficient heat transfer and longevity.

- Military Equipment: Used in armored vehicles, naval vessels, and weapon systems for their toughness and resilience.

- Architectural Hardware: Nickel bars are crafted into bathroom fittings, cabinet hardware, house numbers, and lighting fixtures for decorative and functional purposes.

Need help matching the right nickel alloy bar to your application? What are the best nickel bars for marine or chemical environments? Ask our material specialists for personalized guidance.

Benefits of Nickel Bars

Nickel bars and rods offer a suite of performance advantages that make them the material of choice for demanding industrial, commercial, and scientific uses. Some of the principal benefits include:

- Recyclability: Nickel is highly recyclable, which reduces environmental impact and supports sustainable manufacturing practices.

- Exceptional Toughness: Nickel alloys maintain their strength and integrity even under extreme stress and temperature fluctuations.

- Corrosion Resistance: Nickel and its alloys resist attack from acids, alkalis, seawater, and a wide range of chemical agents, ensuring long service life.

- Hygienic Properties: Nickel bars are ideal for food and pharmaceutical processing due to their easy-to-clean surfaces and resistance to bacterial growth.

- Ductility and Malleability: Nickel can be formed into complex shapes and profiles without compromising structural integrity.

- High Tensile Strength: Nickel bars support heavy loads and withstand mechanical fatigue, making them suitable for structural and load-bearing applications.

- Thermal and Electrical Conductivity: Nickel provides reliable conductivity—vital for electronics, heating elements, and power transmission systems.

- Heat Resistance: Nickel bars retain their properties at elevated temperatures, essential for furnace components and high-temperature processing.

Curious about the environmental impact of nickel bar production or their role in sustainable engineering? How does nickel recycling contribute to green manufacturing? Explore our sustainability resources to learn more.

Decision Factors When Buying Nickel Bars

When sourcing nickel bars, rods, or billets, several key decision factors can help buyers select the optimal product for their needs. Consider the following questions to guide your purchase:

- What is the required alloy composition? Pure nickel, Monel, Inconel, Hastelloy, and other alloys each offer distinct advantages for different applications.

- What are the mechanical property requirements? Consider tensile strength, hardness, ductility, and fatigue resistance for your intended use.

- What environmental conditions will the bars face? Factors such as exposure to chemicals, saltwater, or high temperatures may require specific alloys.

- What size, shape, and tolerance specifications are needed? Ensure your supplier offers custom cutting, finishing, and machining services.

- What are the budget and lead time constraints? Cost, availability, and delivery times can vary by alloy and supplier.

- Is certification or traceability required? Many industries require material certification, mill test reports, and full traceability for quality assurance.

Choosing the Right Nickel Bar Manufacturer

To ensure you have the most positive outcome when purchasing nickel bars from a nickel bar manufacturer, it is important to compare several companies using our directory of nickel bar manufacturers. Each nickel bar manufacturer has a business profile page highlighting their areas of experience and capabilities, along with a contact form to directly communicate with the manufacturer for more information or request a quote. Review each nickel bar business website using our patented website previewer to quickly learn what each company specializes in. Then, use our simple RFQ form to contact multiple nickel bar companies with the same form.

When evaluating suppliers, consider the following:

- Industry Certifications: Look for ISO, ASTM, or other relevant certifications to ensure product quality.

- Technical Support: Leading manufacturers offer engineering support and material selection guidance.

- Customization Capabilities: Some suppliers can deliver bars in custom sizes, shapes, or surface finishes.

- Global Sourcing: Assess supplier networks for international delivery and logistics support.

- Customer Reviews and Reputation: Check testimonials and ratings to verify reliability and service quality.

Ready to get started? Request a quote from multiple nickel bar suppliers to compare pricing, lead times, and technical services for your next project.

Frequently Asked Questions About Nickel Bars

- What is the difference between pure nickel bars and nickel alloy bars?

Pure nickel bars offer maximum corrosion resistance and ductility, while nickel alloy bars are engineered for specific mechanical and chemical properties suited to diverse industrial applications. - How do I select the correct nickel alloy for my application?

Consider the operating environment, required mechanical properties, and any industry standards or certifications. Consult with suppliers or materials engineers for tailored recommendations. - Can nickel bars be recycled?

Yes, nickel is highly recyclable. Recycled nickel bars maintain their performance properties and are widely used in manufacturing, supporting sustainability initiatives. - What are the typical lead times for nickel bar orders?

Lead times vary by alloy, size, and supplier stock levels. Custom orders or specialty alloys may require longer production schedules—request quotes for accurate timelines. - Are certifications available for nickel bars?

Most reputable suppliers provide mill test reports, certificates of analysis, and full traceability upon request. Always specify certification needs when ordering.

Have more questions or need technical advice about nickel bar selection, processing, or sourcing? Contact our team for expert support and application-specific recommendations.

Alloy Suppliers

Alloy Suppliers Aluminum

Aluminum Aluminum Extrusions

Aluminum Extrusions Copper-Brass-Bronze

Copper-Brass-Bronze Magnets

Magnets Nickel

Nickel Stainless Steel

Stainless Steel Stainless Steel Tubing

Stainless Steel Tubing Steel Service Centers

Steel Service Centers Titanium

Titanium Tungsten

Tungsten Wire Rope

Wire Rope Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services